In the context of the continuous upgrading of the global building materials industry, product quality is not only related to the user experience, but also the key to measuring brand strength. DECNO is well aware that only by putting "testing" before manufacturing can the quality be truly controllable and traceable.

This year, as DECNO’s new Hebei production base officially begins operations, a state-of-the-art testing laboratory has been unveiled—designed to be one of North China’s most advanced quality control centers in the flooring and wall panel industry. The lab allows DECNO to run over 20 types of rigorous material and performance tests, ensuring that every product leaving the facility meets the highest international standards for safety, stability, and longevity.

20+ Testing Items, Full Process Coverage

The laboratory of DECNO Hebei base is equipped with multiple international standard equipment, covering multiple dimensions such as performance testing, surface treatment testing, stability testing, environmental tolerance testing, etc., which can independently complete the following:

Raw material whiteness/calcium content/moisture content

Locking Tensile Strength

Martindale testing

Scratch Resistance

Static bending strength

Falling-Ball Tensile Force Inspection

Weathering resistance

……

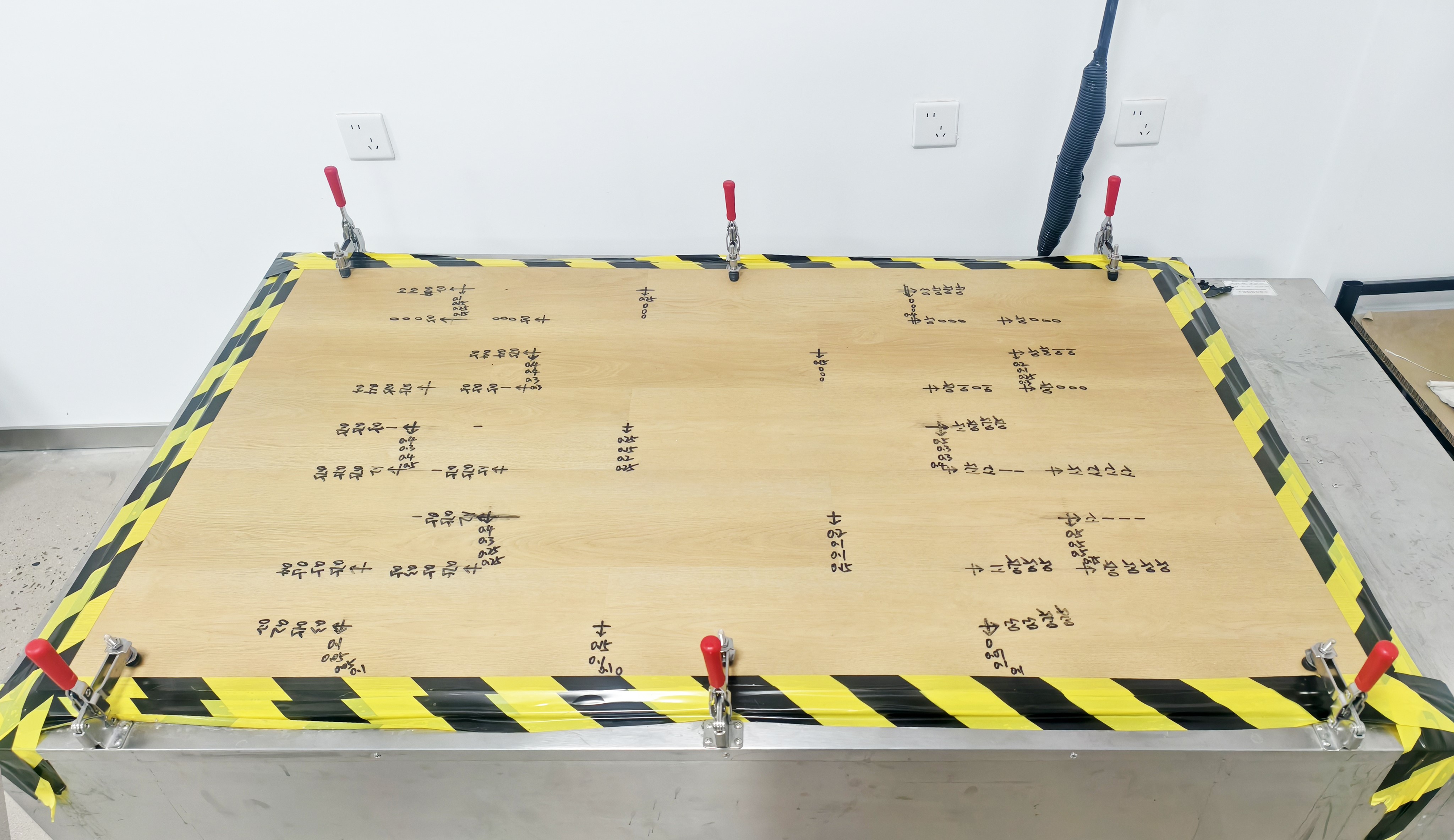

Key project: Weathering resistance test, verifying the answer of "time"

DECNO attaches great importance to the weathering resistance of SPC floor, which is an important indicator to judge whether the product will fade, deform, become brittle, or become unstable in the actual environment.

DECNO weathering resistance test equipment is the only one in northern China that can test the whole splicing board. By simulating the floor heating environment, the sample is laid for a duration of up to 720 hours. At the same time, the experimental environment reaches 50° high temperature and 90° high humidity, which can not only test the performance of single-piece boards, but also the performance of lock splicing, overall assembly effect, etc.

According to the experiment, DECNO's SPC floor can achieve no visible deformation effect, which can increase the life of the floor to more than 15 years, and reduce the replacement cost by 47% compared with solid wood flooring (average service life of 8 years). Whether in the home or commercial field, it is an excellent choice.

Experimentation First, and Assurance Also

From R&D, prototyping to mass production, DECNO regards experimentation as a key part of the product process. Every experiment is a verification of the product's limit; every piece of data is a response to the quality commitment.

By placing testing and quality validation at the heart of production, DECNO builds not only reliable products—but also reliable trust. This laboratory will continue to serve as a foundation for innovation, excellence, and global expansion.